Projects

McClean Lake Project

McClean Lake Deposits and Mill

As we continue to advance this exciting project we will post the latest maps and photos. Click icons to view.

Detailed

Maps

Detailed Maps

Drone

Video

Drone Video

Featured

Video

Featured Video

Featured Video Pending.

Project Highlights

Annual licensed production capacity of 24M lbs U3O8

Operating licence for the McClean Lake operation renewed by the CNSC for a 10-year period in 2017, and amended in 2022 to include authorization for expansion of tailings management facility.

Processed ~18M lbs U3O8 from the Cigar Lake mine in 2022, under a toll milling agreement.

Denison monetized Cigar Lake toll milling cash flow in transaction with Anglo Pacific Group (“APG”) in 2017 for $43.5M

Historic production from McClean Lake deposits of ~50M lbs U3O8 from the Sue (A, B, C and E) and JEB deposits

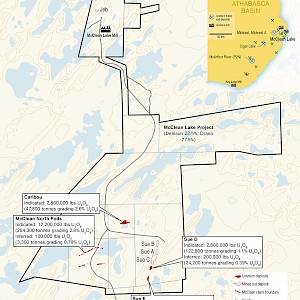

Host to undeveloped McClean North, Caribou, Sue D and Sue E uranium deposits

Location

The McClean Lake property is located within the eastern part of the Athabasca Basin in northern Saskatchewan, approximately 26 kilometres west of the Rabbit Lake mine and approximately 750 kilometres north of Saskatoon.Access to the McClean Lake site is by both road and air.Goods are transported to the site by truck over an all–weather road connecting with the provincial highway system.Air transportation is provided through the Points North airstrip about 25 kilometres from the project site

Ownership

The McClean Lake projects are owned by Denison (22.5%) and its joint venture partner, Orano Canada (77.5%). Orano Canada is the operator/manager of the projects.

McClean Lake Mill

The McClean Lake uranium mill, one of the world’s largest uranium processing facilities, is currently processing ore from the Cigar Lake mine under the Cigar toll milling arrangement between the MLJV and the CLJV. Mill construction commenced in 1995 and ore processing activities reached commercial production in November 1999.Mining operations also commenced, and the following deposits have been mined out to date:JEB (1996 to 1997), Sue C (1997 to 2002), Sue A (2005 to 2006), Sue E (2005 to 2008) and Sue B (2007 to 2008). Various test mining programs from 2006 to date have also been conducted at McClean North.The site consists of the mill, a tailings management facility, administration offices and building, camp facilities, back-up power supply, water treatment plants and a host of other minor facilities. The site is connected to the provincial power grid and provincial highways.

As a uranium site, the CNSC permits the operations. The McClean site has a 10-year license for operations, expiring June 2027.

McClean Lake Deposits & Exploration

The McClean Lake uranium deposits lie near the eastern margin of the Athabasca Basin in the Churchill Structural Province of the Canadian Shield.The McClean Lake uranium deposits which include the Sue deposits (A to E), McClean deposits (North and South), Caribou deposit and JEB deposit are unconformity-related deposits of the unconformity-hosted variety.

Exploration activities including ground geophysics and diamond drilling were conducted by Orano Canada from 1994 to present.The majority of exploration has been focused on areas of known mineralization at McClean North/South, Sue Trend, JEB and the Tent Seal Trend. Other target areas on the property which have also been subject to ground geophysics and drilling include Candy Lake, Bena, Vulture and Moffat Lake. In 2002 the discovery of Caribou, the high- grade unconformity related uranium deposit was made approximately 2 kilometres northwest of the Sue C open pit. No other significant discoveries have been made since 2002. During the period 1994 to 2017 Orano Canada completed 95,933 metres of drilling in 496 holes.

Estimated Mineral Reserves and Resources

|

Deposit |

Classification |

Tonnes |

Grade % U3O8 |

M Lbs U3O8 |

Denison |

|

McClean Ore Stockpile |

Proven Reserve |

88,000 |

0.38 |

0.7 |

0.2 |

|

McClean North |

Indicated |

205,800 |

2.8 |

12.4 |

2.8 |

|

Caribou |

Indicated |

47,800 |

2.6 |

2.8 |

0.6 |

|

Sue D |

Indicated |

122,800 |

1.1 |

2.8 |

0.6 |

|

Sue E |

Inferred |

483,400 |

0.69 |

7.3 |

1.6 |

Notes:

- The Mineral Resource estimates were prepared for the Company by Scott Wilson RPA (now SLR Consulting Inc.) in accordance with CIM Definition Standards and NI 43-101.

- Mineral Resources are reported above a cut-off grade of 0.1% U3O8.

References

McClean Lake: Technical Report on the Denison Mines Inc. Uranium Properties, Saskatchewan, Canada, dated November 21, 2005, as revised February 16, 2006, by Richard E. Routledge, M.Sc., P.Geo of Scott Wilson RPA (now RPA Inc.)

McClean Lake - Sue D: Technical Report on the Sue D Uranium Deposit Mineral Resource Estimate, Saskatchewan, Canada, dated March 31, 2006, by Richard E. Routledge, M.Sc., P.Geo and James W. Hendry, P.Eng of Scott Wilson RPA (now RPA Inc.).

McClean Lake – McClean North: Technical Report on the McClean North Uranium Deposit Mineral Resource Estimate, Saskatchewan, Canada, dated January 31, 2007, by Richard E. Routledge, M.Sc., P.Geo and James W. Hendry, P.Eng of Scott Wilson RPA (now RPA Inc.), and subsequent revision by letter dated October 20, 2009 from Scott Wilson RPA.

The information of a scientific and technical nature has been reviewed and approved by a Qualified Person in accordance with the requirements of NI 43-101.

- Home

- About Us

- Projects

- Investors

- News

- Denison Receives Final Regulatory Approval to Construct the Phoenix ISR Uranium Mine

- Denison Announces Award of Construction Management Contract to Wood Canada for the Phoenix Uranium Mine

- Denison Announces Grid Power Available at Future Phoenix Uranium Mine Site Following Completion of SaskPower Transmission Line

- Denison Reports Readiness to Commence Construction of Flagship Phoenix ISR Project and Provides Capital Cost Update

- Denison Announces Closing of Transaction with Skyharbour and Formation of Four Prospective Exploration Joint Ventures Proximal to Wheeler River

- Denison Announces Signing of Impact Benefit Agreement and Exploration Agreement with Métis Nation-Saskatchewan, MN-S NR-1, and MN-S NR-3

- Denison & Ya'thi Néné Lands and Resources Announce Signing of the Nuhenéné Benefit Agreement with Three First Nations and Four Municipalities

- Denison Announces Agreements with Skyharbour Resources, Increasing Denison's Strategic Foothold Surrounding Wheeler River

- Denison Reports Financial and Operational Results for Q3 2025, Including First Production from McClean North Uranium Mine

- Denison Acknowledges Application for Judicial Review Regarding Provincial Environmental Assessment Approval for Wheeler River

- Denison to File Early Warning Report in Respect of Foremost Clean Energy Ltd.

- Denison Announces Closing of US$345 Million Convertible Senior Notes Offering

- Denison Announces Pricing of Upsized US$300 Million Convertible Senior Notes Offering

- Denison Announces Offering of US$250 Million of Convertible Senior Notes

- Denison Reports Financial and Operational Results for Q2 2025, Highlighted by Return to Uranium Production at McClean Lake and Provincial Approval of Wheeler River Environmental Assessment

- Denison Announces Results from Midwest ISR Preliminary Economic Assessment, Including After-Tax NPV of $965 Million

- Denison Receives Provincial Environmental Assessment Approval for the Wheeler River Project

- Denison Announces Additional High-Grade Uranium Mineralization Discovered at McClean South

- Orano Canada and Denison Announce SABRE 1st Production at McClean Lake

- Denison Announces Discovery of Additional High-Grade Mineralization at Gryphon and Reports Results from Successful Delineation Program

- Denison Reports Financial and Operational Results for Q1 2025, Highlighted by Continued Advancement of the Phoenix Project, and the Results of its Shareholder Meeting

- Denison Announces Filing of Annual Report on Form 40-F

- Denison Announces Appointment of Former OPG CEO Ken Hartwick to its Board of Directors

- Denison Reports Financial and Operational Results for 2024 Highlighted by Significant Advancement of the Phoenix Project

- Denison Reports CNSC Hearing Dates for Phoenix ISR Project

- Denison Announces Agreement to Form Exploration Joint Ventures with Cosa Resources

- Denison Files Final Wheeler River Environmental Impact Statement with CNSC Following Completion of Technical Review

- Denison to File Early Warning Report in Respect of Foremost Clean Energy Ltd.

- Denison Reports Financial and Operational Results for Q3'2024, Including Positive Progress on Phoenix Engineering and Regulatory Review

- Denison Files Early Warning Report in Respect of Foremost Clean Energy Ltd.

- Denison Announces Option of Non-Core Exploration Projects to Foremost for up to $30 Million in Combined Consideration

- Denison CEO Highlights Phoenix Post-Feasibility Study Progress and Company Reports Financial and Operational Results for Q2'2024

- Denison Announces Signing of Wheeler River Benefit Agreements with Kineepik Métis Local #9 and the Village of Pinehouse Lake

- Denison Announces Completion of Inaugural ISR Field Test Program at Midwest

- Denison Announces Results of Shareholder Meeting & Appointment of Jennifer Traub as Board Chair

- Denison Reports Financial and Operational Results for Q1 2024

- Denison Announces Filing of Annual Report on Form 40-F

- Denison Announces Signing of Sustainable Communities Investment Agreement

- Denison Reports Impressive Financial and Operational Results for 2023 Including Significant Increase in Phoenix ISR Project Economics and a $134 Million Gain on Physical Uranium Holdings

- Denison Announces Exclusive Acquisition of MaxPERF Tool Systems, Enhancing Denison's Leadership in ISR Mining in the Athabasca Basin

- Orano Canada and Denison Announce JV Approval to Restart McClean Lake Mining Operations

- Denison Announces $16 Million Contract Award to Wood for Completion of Detailed Design Engineering for Flagship Phoenix ISR Project

- Denison Reports Appointment of Elizabeth Sidle as CFO and Addition of Geoff Smith to Executive Team

- Denison Reports Financial Results from Q3'2023, Including EPS of $0.07 Driven by Significant Gains on Physical Uranium Holdings

- Denison Announces Successful Completion of Inaugural ISR Field Test Program at Tthe Heldeth Túé (THT)

- Denison Announces Successful Completion of Recovered Solution Management Phase of Phoenix ISR Feasibility Field Test

- Denison Completes US$55 Million Offering to Fund Long-Lead Procurement for Phoenix ISR Project

- Denison Announces US$55 Million Bought Deal Offering

- Denison Announces $15 million Strategic Investment in F3

- Denison Announces Signing of Landmark Shared Prosperity Agreement with English River First Nation

- Denison CFO on Temporary Medical Leave of Absence, Interim CFO Appointed

- Denison Reports Financial and Operational Results for Q2 2023

- Denison Announces Filing of Technical Report for Wheeler River

- Denison Reports Significant Increase in Economic Results for Wheeler River

- Denison Announces Results of Shareholder Meeting

- Denison Reports Financial and Operational Results for Q1 2023

- Denison Announces Discovery of High-Grade Uranium Mineralization at Moon Lake South

- Denison Releases 2022 ESG Report, Highlighting Progress on Environmental, Social and Governance Initiatives

- Denison Announces Completion of Conceptual Mining Study Evaluating ISR for Midwest and Plans to Advance Efforts in 2023

- Denison Announces Filing of Annual Report on Form 40-F

- Denison Reports Financial and Operational Results for 2022, Including Significant De-Risking and Regulatory Milestones

- Denison Announces Successful Completion of Neutralization Phase of Phoenix ISR Feasibility Field Test

- Denison Announces 97% Recovery from Long-Term Phoenix ISR Core Leach Test

- Denison Announces Completion of Wheeler River EIS Conformity Review and Commencement of Technical Review

- Denison Announces Additional Highlights from Highly Successful Leaching Phase of Phoenix ISR Feasibility Field Test

- Denison Reports Financial and Operational Results for Q3 2022, Including Significant De-Risking and Regulatory Milestones

- Denison Announces Significant Regulatory Milestone for Wheeler River with Submission of Environmental Impact Statement

- Denison Announces Exploration Agreement with the Ya'thi Néné Lands and Resources Office, the Athabasca Nations, and Communities of the Nuhenéné

- Denison Announces History-Making Recovery of Uranium Bearing Solution from Phoenix ISR Feasibility Field Test

- Denison Completes Commissioning of Lixiviant Injection Modules for Phoenix ISR Feasibility Field Test

- Denison Announces Intersection of Additional High-Grade Uranium Mineralization at Waterfound

- Denison Announces Expansion of High-Grade Uranium Mineralization at McClean Lake South

- Denison Delivers Further Acquisition Proposal to UEX

- Denison Announces Phoenix ISR Feasibility Field Test is Fully Permitted

- Denison Announces Expiry of Offer to Acquire UEX

- Denison Reports Financial and Operational Results for Q2 2022, Including Uranium Sales from Production at $74.65 per lb U3O8

- Denison Achieves Key Milestone with Completion of Metallurgical Test Work to Define Phoenix Process Plant Components and Confirmation of Ability to Produce Yellowcake

- Denison Confirms Superior Proposal for UEX Corporation

- Denison Receives Approval to Construct and Operate Phoenix Feasibility Field Test Facility from Saskatchewan Minister of Environment

- Denison Announces Execution of Agreements with Kineepik Métis Local #9

- Denison Reports Financial and Operational Results for Q1 2022, including $47.8 million gain on Physical Uranium Holdings

- Denison Announces Results of Shareholder Meeting

- Denison Announces Discovery of High-Grade Uranium Mineralization At 24.68% Owned Waterfound JV

- Denison Announces Filing of Annual Report on Form 40-F

- Denison Reports Strong Operational and Financial Results for 2021 Backed by Improving Uranium Market and $41.4 million gain on Physical Uranium Holdings

- Denison Announces Intersection of 24.9% eU3O8 over 4.2 metres extending beyond high-grade domain at Phoenix Zone A

- Denison Announces Board and Management Additions

- Denison Announces 22.5% Owned McClean Lake Operation Granted Approval to Expand Tailings Management Facility

- Denison Negotiates Repayment of Debt Owing from Uranium Industry A.S. and Receives Initial US$2 million Payment

- Denison Announces Adoption of Indigenous Peoples Policy

- Denison Reports Results from Q3 2021

- Orano and Denison Announce Successful 2021 Mining Test Showcasing SABRE Potential

- Denison Announces Completion of Highly Successful Phoenix ISR Field Test Program

- Denison Completes Sale of GoviEx Shares and Warrants

- Denison Announces Sale of Goviex Shares and Warrants for up to $41.6 Million

- Denison Announces At the Market Offering Agreement With Cantor Fitzgerald & Scotia Capital

- Denison Announces Decision to Advance Wheeler River to Feasibility Study Stage and Selection of Wood PLC as Independent Lead Author

- Denison Receives $20.45 Million From UEX To Settle Loan From JCU Transaction

- Denison Reports Results from Q2 2021

- Denison Reports Decision to Increase Anticipated ISR Mining Head Grade at Phoenix by 50%

- Denison Acquires 50% of JCU (Canada) Exploration Company, Limited and Increases Effective Interest in Wheeler River to 95%

- Denison Provides Interim Progress Update on ISR Field Test Activities and Announces Discovery of Additional High-Grade Uranium Mineralization at Phoenix

- Denison Announces Agreement to Acquire 50% of JCU (Canada) Exploration Company, Limited from UEX Corporation for $20.5 Million

- Denison Announces Appointment of Ron Hochstein as Board Chair and Welcomes New Directors

- Denison Announces Results of Shareholder Meeting

- Denison Reports Results from Q1 2021

- Denison Delivers Offer to Acquire 100% Ownership of JCU (Canada) Exploration Company, Limited

- Denison to Receive Approximately $5.3 Million in Connection with Termination of UPC Management Services Agreement

- Denison Provides Initial Progress Update on Installation of ISR Test Pattern at Wheeler River

- Denison Announces Discovery Of High-Grade Uranium Mineralization At McClean Lake South

- Denison Announces Execution of Agreements with the English River First Nation

- Denison Announces Successful Procurement of 2.5 Million Lbs U3O8 as Part of Project Finance Initiative

- Denison Announces Filing of Annual Report on Form 40-F

- Denison Announces Closing of US$86.3 Million Financing in Support of Strategic Acquisition of Physical Uranium

- Denison Announces Funding of Project Finance Initiative Involving Strategic Acquisition of Physical Uranium

- Denison Announces Inclusion in the S&P/TSX Composite Index

- Denison Reports a Year of Significant Project and Company De-Risking

- Denison Completes Bought Deal Private Placement of Flow-Through Shares for Proceeds of $8 Million

- Denison Announces Closing of US$28.75 Million Bought Deal Offering of Units

- Denison Announces USD$25 Million Bought Deal Offering of Units and CAD$8 Million Bought Deal Private Placement of Flow-Through Shares

- Denison Announces 2020 Phoenix Expansion Drilling Returns Best Results to date at Zone C

- Denison Announces Ramp-Up of Wheeler River Evaluation Activities in 2021

- Denison Announces Discovery of High-grade Uranium Mineralization Four Kilometres Northwest of Phoenix

- Denison Completes Private Placement of Flow-Through Shares for Proceeds of Approx. CAD$930,000

- Denison Reports Filing of Technical Report for Waterbury PEA

- Denison Announces Decision to Adopt Freeze Wall Design for ISR Mining at Phoenix

- Denison Reports Results From Waterbury PEA, Including Base Case Pre-Tax NPV of $177M and IRR of +39.1%

- Denison Announces Establishment of At-The-Market Program

- Denison announces decision to resume formal Environmental Assessment process for Wheeler River

- Denison Reports Results From Q3 2020

- Denison Announces Completion of ISR Field Program and Initiation of Exploration Program at Wheeler River

- Denison Completes US$19.0 Million Offering

- Denison Increases Bought Deal Offering to US$17.4 Million

- Denison Announces US$10 Million Bought Deal Offering

- Denison Reports Results From Q2 2020

- Denison Announces Positive Arbitration Ruling Related to Sale of Mongolian Assets

- Denison Announces Completion of Conceptual Mining Study Evaluating ISR Mining Method for J Zone and Decision to Initiate Preliminary Economic Assessment

- Denison Announces Resumption of ISR Field Testing Activities at Phoenix With Commencement of 2020 ISR Field Program

- Denison Announces Results of Shareholder Meeting

- Denison Announces Independent "Proof of Concept" Achieved for Application of ISR Mining Method at Phoenix and Details of 2020 ISR Field Program

- Denison Reports Results From Q1 2020

- Denison Completes USD$5.75 Million Public Offering

- Denison Announces US$5 Million Public Offering

- Denison Announces Overnight Marketed Offering

- Denison Announces Temporary Suspension of Wheeler River Environmental Assessment Amidst COVID-19 Disruptions

- Denison Announces Filing of Annual Report on Form 40-F

- Denison Reports Results from 2019

- Denison Reports Results From Phoenix ISR Field Tests Confirm Ability to Achieve Hydraulic Conductivity Values Consistent With Pre-Feasibility Study

- Denison Reports Uranium Concentrations from Initial Core Leach Tests up to Four Times the Amount Assumed in Pre-Feasibility Study for Phoenix ISR Operation

- Denison Reports Completion of Highly Successful 2019 ISR Field Test at the Phoenix Deposit and Initiation of ISR Metallurgical Testing

- Denison Completes CAD$4.7 Million Bought Deal Private Placement of Flow-Through Shares

- Denison Announces CAD$4.1 Million Bought Deal Private Placement of Flow-Through Shares

- Denison Reports Results from Q3 2019

- Denison Reports Installation of Commercial Scale Wells and Provides Operational Update from Ongoing ISR Field Test at the Phoenix Deposit

- Denison Announces Appointment of David Bronkhorst as Vice President Operations

- Denison Reports Initial Results from ISR Field Test at Phoenix Test Area 2 and Advancement to Commercial Scale Wells

- Denison Announces Positive Initial Results from ISR Field Test Program at Phoenix Test Area 1

- Denison Reports Results from Q2 2019

- Denison Announces Initiation of ISR Field Testing as the Summer Field Program Commences at Wheeler River

- Denison Announces Initiation of Environmental Impact Assessment Process and Execution of MOU with Local Communities for the Wheeler River Project

- Denison Announces Results of Shareholder Meeting

- Denison Reports Results from Q1 2019

- Denison Announces Five-Year Management Services Agreement with Uranium Participation Corporation

- Denison announces filing of annual report on Form 40-F

- Denison Reports Results from 2018 and Outlook for 2019

- Denison Announces 2019 Exploration Program Focused on High Potential Properties

- Denison Announces Filing of Technical Report for Waterbury Lake Property

- Denison Announces Decision To Advance Wheeler River Project Following Positive PFS Results

- Denison Completes CAD$5 Million Bought Deal Private Placement of Flow-Through Shares

- Denison Reports Results from Q3 2018

- Denison Annouces CAD$5 Million Bought Deal Private Placement of Flow-Through Shares

- Denison Announces Filing of Technical Report for Wheeler River PFS

- Denison Announces Completion of Transaction to Increase Interest in the Wheeler River Uranium Project to 90%

- Denison Reports Results from Wheeler River PFS, Including +275% Increase in Pre-Tax NPV and Selection of ISR Mining Method for Phoenix Deposit

- Denison Discovers Uranium Mineralization Three Kilometres Northeast of the Huskie Zone, Waterbury Lake Project

- Denison Announces Appointment of Tim Gabruch as Vice President Commercial

- Denison to increase its interest in the Wheeler River Uranium Project

- Denison Announces Board Appointments

- Denison Reports Results from Q2 2018

- Denison President & CEO Appointed to Board of Directors of Canadian Nuclear Association

- Denison Announces Summer Drilling Plans for Wheeler River and Reports Winter Assay Results

- Denison Announces Summer 2018 Exploration Plans for High-priority Pipeline Projects

- Denison Announces Results of Shareholder Meeting

- Denison Reports Results from Q1 2018

- Denison Reports Expansion Of The Huskie Zone With Intersection Of 4.5% U3O8 Over 6.0 Metres

- Denison Reports High-Grade Uranium Intercepts Northeast of the Gryphon Deposit

- Denison Announces Filing of Annual Report on Form 40-F

- Denison Announces Increase in Mineral Resources Estimated for the Midwest Uranium Project

- Denison Announces Filing of Technical Report for Wheeler River

- Denison Reports Results From 2017 and Outlook for 2018

- Denison Announces 88% Increase in Indicated Resources at Wheeler River With Updated Mineral Resource Estimate for the Gryphon Deposit

- Denison Announces 2018 Exploration & Evaluation Program Focused on High Priority Properties

- Denison Announces Stantec & ENGCOMP to Lead Pre-Feasibility Study for Wheeler River Project and Provides Update on Status of Gryphon Resource Estimate

- Denison Reports Wheeler River Summer Assays Ahead of Resource Estimate

- Denison Extends High-Grade Unconformity Mineralization Near the Gryphon Deposit with 4.3% eU3O8 over 4.3 Metres and Completes Summer Drilling at Wheeler

- Denison Reports Q3 2017 Results

- Denison Reports 9.1% U3O8 Over 3.7 Metres From the High-Grade Huskie Zone at Waterbury Lake With Receipt of Assays

- Denison Announces Further Extension of High-Grade "Huskie" Zone at Waterbury Lake With Final Summer Drill Holes

- Denison Announces Significant Increase to Summer 2017 Drilling Program at Wheeler River

- Denison Intersects 5.0% eU3O8 Over 4.7 Metres at the Unconformity as Definition and Expansion Drilling Continues on the Gryphon Deposit at Wheeler River

- Denison Reports 3.7% eU3O8 Over 3.9 Metres From Initial Follow Up Drilling at New High-Grade Basement Uranium Discovery at Waterbury Lake

- Denison Reports Q2 2017 Results Including Highlights From Promising Summer 2017 Exploration Program

- Denison Reports New High-Grade Uranium Discovery on the Waterbury Lake Property

- Denison Reports New High-Grade Uranium Discovery on the Waterbury Lake Property

- Denison Reports Extension of Cornerstone Contract for Environmental Services Business

- Denison Reports 25 Metres of 1.3% eU3O8 as Gryphon Exploration Continues at Wheeler River

- Why now is the time to invest in uranium

- Why countries use nuclear power over other sources of energy

- Denison Announces 22.5% Owned McClean Lake Operations Granted 10-Year Licence Renewal by CNSC

- Denison Announces Active Summer Plans for Wheeler River and Pipeline Projects

- Denison Reports Assays Increase Grades by 45% and Deliver Most Meaningful Gryphon D-Lens Result to Date at Wheeler River

- Denison Announces Election of Directors

- Is the growth of the uranium mining sector related to the future of nuclear energy?

- Denison Reports Q1 2017 Results Including Highlights From Successful Winter 2017 Exploration Programs

- Denison Announces 22.1 Metres of High-Grade Mineralization From Gryphon D Series as Winter Drilling Wraps Up at Wheeler River

- Denison Announces Filing of Annual Report on Form 40-F

- Denison Continues to Expand Gryphon D Series Lenses With Multiple High-Grade Mineralized Intersections

- What is driving the massive nuclear build outs?

- Denison Completes CAD$20M Bought Deal Private Placement of Common and Flow-Through Shares

- Denison Reports Results from 2016 and Outlook for 2017

- Denison Announces CAD$20M Bought Deal Private Placement of Common and Flow-Through Shares

- Denison Announces Closing of CAD$43.5M Financing Arrangement With Anglo Pacific Group PLC

- Where is the growth in demand of uranium coming from?

- Denison Announces CAD$43.5M Financing Arrangement With Anglo Pacific Group PLC

- Denison Announces Focused CAD$14.5M Exploration and Evaluation Program Budget for 2017

- The importance of nuclear in the world's energy mix

- Denison Executes Agreement to Increase Ownership of Wheeler River Project Up to 66%

- CEO David Cates on how the uranium market functions differently when compared to the more mainstream commodities

- CEO David Cates on who are the main consumers of uranium?

- Denison Reports 6.97% U3O8 Over 4.5 Metres and Confirms Expansion of High Grade Mineralization at the Gryphon Deposit, Wheeler River

- Denison announces completion of Hook-Carter acquisition and purchase of Coppin Lake property

- Denison Reports Q3 2016 Results Including Highlights From Successful Summer 2016 Exploration Programs

- CEO David Cates on the "Real" Price of Uranium

- Denison Reports on Initial Project Development Activities at Wheeler River

- CEO David Cates on the Mechanics of Uranium Pricing: Spot price versus Long-term price

- CEO David Cates on Denison's relationship with Uranium Participation Corp. (TSX:U)

- Denison Announces Transaction to Acquire the Hook-Carter Property From ALX Uranium Corp.

- Denison Completes Highly Successful Summer 2016 Drilling Program at Wheeler River

- Denison Expands High-Grade Mineralization of Gryphon Deposit as Drilling Continues at Wheeler River

- Denison Expands Strike Length of Gryphon D Series Lenses and Announces Plans for Follow-Up Drilling at K-West on Wheeler River

- Denison Announces Receipt of Skyharbour Shares in Connection With Option of Moore Lake Property to Skyharbour for Cash and Shares

- Denison Reports Results From Encouraging Q2 2016, Including Further Exploration Success and Initiation of Pre-Feasibility Study at Wheeler River

- Denison Announces Initiation of Pre-Feasibility Study and Result of First Infill Drill Hole at Wheeler River Gryphon Deposit

- Denison Announces Transaction to Option Moore Lake Property to Skyharbour for Cash and Stock

- GoviEx and Denison Successfully Complete Transaction to Combine African Uranium Mineral Interests

- Denison Reports McClean Lake Mill Obtains Regulatory Authorization to Produce Up to 24 Mlbs U3O8 Per Year

- Denison Reports Increased Grades With Receipt of Wheeler Assay Results and Announces Summer 2016 Exploration Priorities

- Denison Completes Bought Deal Offering of Flow-Through Common Shares

- GoviEx and Denison Provide Transaction Update

- Denison Announces Filing of Technical Report for Wheeler River PEA

- Denison Announces Election of Directors

- Denison Reports Results From Active Q1 2016, Including Positive Economics for Wheeler River and Sale of African Assets

- Denison Mines Announces CAD$10 Million Bought Deal Offering of Flow-Through Common Shares

- Denison Reports Highlights From Winter Drilling on Eastern Athabasca Basin Exploration Pipeline Projects

- Denison Announces Expansion of Gryphon Mineralization as Winter Exploration Drilling Wraps Up at Wheeler River

- Denison Reports Results From Wheeler River PEA, Including Pre-Tax IRR of +20% at Current Uranium Prices and Initial CAPEX of CAD$336M

- Denison and GoviEx to Combine African Uranium Assets

- Denison Announces Filing of Annual Report on Form 40-F

- Denison Announces Positive Metallurgical Test Results for the Gryphon Deposit

- Denison Intersects 3.9% eU3O8 Over 9.2 Metres, Including 6.7% eU3O8 Over 5.3 Metres, Near the Gryphon Deposit

- Denison Mines Corp. Reports Highlights of 2015 Results

- Denison Announces Execution of Three Year Management Services Agreement With Uranium Participation Corporation

- Denison Announces Intersection of High-Grade Uranium Mineralization Near the Gryphon Deposit

- Denison Announces Start of 2016 Athabasca Basin Exploration Programs and 2016 Budget Highlights

- Denison Receives US$1.25 Million in Initial Payments on Closing of the Sale of Mongolian Interests

- Denison Mines Corp. Reports Third Quarter 2015 Results

- Denison Announces Significant Increase in Wheeler River Resource with 43 Million lb Initial Estimate for Gryphon

- Denison Completes Summer Exploration Activities

- Denison Appoints Lukas Lundin Executive Chairman and Provides Corporate Update

- Denison and Fission Terminate Arrangement Agreement

- Voting in Favour of Denison/Fission Merger Recommended by Leading Independent Proxy Advisory Firms

- Denison to Co-Host Town Hall Meeting Regarding Denison/Fission Merger on October 6, 2015 at Royal York Hotel in Toronto at 4:30 P.M.

- Denison Mines Corp. Reports Second Quarter 2015 Results

- Denison Mines Corp. Announces Agreement to Sell Mongolian Interests to Uranium Industry a.s.

- Denison Completes Gryphon Definition Drilling and Discovers Uranium Mineralization at Murphy Lake

- Denison and Fission Execute Definitive Arrangement Agreement

- Denison and Fission Announce Transaction to Create Leading Diversified Uranium Company

- Denison Begins Summer Exploration Program and Receives Assays From Gryphon Zone

- Denison Mines Completes CAD$15,000,000 Bought Deal Offering

- Denison Announces Election of Directors

- Denison Mines Corp. Reports First Quarter 2015 Results

- Denison Mines Announces $15 Million Bought Deal Offering of Flow-Through Common Shares

- Denison Completes Successful Winter Drilling Season

- Denison Intersects New Zone of Uranium Mineralization at Wheeler River

- Denison Announces Changes to Executive Team

- Denison Mines Files Annual Report on Form 40-F

- Denison Mines Corp. Reports 2014 Results

- Denison Announces High Grade Uranium Drill Intersections at Mann Lake and Wheeler River

- Denison Announces Management Change and Start of 2015 Athabasca Basin Exploration Programs

- Denison Receives Additional Assays from Gryphon Including 22.2% U3O8 Over 2.5 Metres Plus Positive Preliminary Phoenix Metallurgical Testwork

- Denison Mines Corp. Reports Third Quarter 2014 Results

- Denison Appoints Peter Longo as Vice President Project Development

- Denison Extends Gryphon Zone at Wheeler River Project and Completes Summer Drilling Programs

- Denison Mines Corp. Completes C$14,997,150 Flow-Through Share Offering

- Denison Mines Corp. Reports Second Quarter 2014 Results

- Denison Announces Initial Summer Drilling Results from the Gryphon Zone at Wheeler River

- Denison Mines Announces $13 Million Bought Deal Offering of Flow-Through Common Shares

- Denison Announces Phoenix Uranium Deposit Mineral Resource Estimate Now Over 70 Million Pounds

- Denison Adds Exciting New Uranium Discovery to Its Athabasca Portfolio With IEC Closing

- Denison Announces 21.2% U3O8 Over 4.5 Metres From the Gryphon Zone at Wheeler River

- Denison Announces Election of Directors

- Denison Mines Corp. Reports First Quarter 2014 Results

- Denison Announces 36.83% U3O8 Over 6.5 Metres From Zone A of the Phoenix Deposit

- Denison Mines Corp. Announces Definitive Agreement for Acquisition of International Enexco Limited

- Denison Intersects 17.3% Uranium Over 4.2 Metres in Follow-Up Drill Hole at the Gryphon Zone

- Denison Intersects High Grade Uranium at a New Target Area at Wheeler River

- Denison Mines Corp. Announces Letter of Intent for Acquisition of International Enexco Limited

- Denison Mines Files Annual Report on Form 40-F

- Denison Mines Corp. Reports 2013 Results

- Denison Announces High Grade Uranium Intersections at the Phoenix Deposit

- Denison Closes Arrangement With Rockgate Capital Corp.

- Denison Announces Start of 2014 Athabasca Basin Exploration Programs

- Denison Options Jasper Lake Uranium Property to Strateco

- Denison Acquires 89% of Rockgate and Announces Intention to Acquire Remaining Shares Through a Plan of Arrangement

- Denison Acquires Additional Shares of Rockgate and Extends Offer to December 6, 2013

- Denison Acquires 86% of Rockgate and Extends Offer to November 29, 2013

- Denison Mines Corp. Reports Third Quarter 2013 Results

- Denison Extends Takeover Bid for Rockgate to November 18, 2013 and Lowers Minimum Tender Condition to 66 2/3%

- Denison Extends Takeover Bid for Rockgate to November 1, 2013

- Denison Opposes Management Entrenchment by Rockgate

- Denison Formally Commences Rockgate Takeover Offer

- Denison Announces Superior Takeover Offer for Rockgate Capital Corp.

- CORRECTION FROM SOURCE: Denison Files New Technical Report on Mutanga Uranium Project

- Denison Files New Technical Report on Mutanga Uranium Project

- Denison Completes Mineral Resource Estimate on the J Zone Uranium Deposit

- Denison Adds Additional High Grade Intersections at the Phoenix A Deposit

- Denison Mines Corp. Reports Second Quarter 2013 Results

- CORRECTION FROM SOURCE: Denison Intersects 43.2% eU3O8 Over 10.3 Metres at Wheeler River

- Denison Intersects 43.2% eU3O8 Over 10.3 Metres at Wheeler River

- Denison Mines Corp. Completes CDN$14,950,000 Flow-Through Share Offering

- Denison Mines Corp. Completes CDN$14,950,000 Flow-Through Share Offering

- Denison Mines Announces Election of Directors

- Denison Mines Corp. Reports First Quarter 2013 Results

- Denison Closes Arrangement with Fission Energy Corp.

- Denison Expands the 489 Zone at Wheeler River

- Denison Files Annual Report on Form 40-F

- Denison Identifies New Area of Interest at Wheeler River and Provides Exploration Update

- Denison Mines Corp. Reports 2012 Results

- Denison Mines Corp. and Fission Energy Corp. Execute Definitive Arrangement Agreement

- Denison Mines Announces Closing Of Acquisition of JNR Resources Inc.

- Denison Mines Announces Closing Of Acquisition of JNR Resources Inc.

- Denison Mines to Acquire Fission Energy and Spin Out Patterson Lake

- Denison Announces 2013 Exploration and Development Plans

- Denison Announces Significant Increase in Mineral Resource Estimates for the Phoenix Deposits

- Denison Mines Corp. Files Early Warning Report in Respect of International Enexco Ltd.

- Denison Mines Corp. Announces Plan of Arrangement with JNR Resources Inc.

- Denison Mines Corp. Announces Agreement to Acquire JNR Resources Inc.

- Denison Mines Corp. Reports Third Quarter 2012 Results

- Denison Mines Corp. Completes $7.0 Million Flow-Through Share Offering

- Denison Announces 2012 Drilling Results from the Wheeler River Property, Saskatchewan

- Denison Announces 2012 Phase 1 Drilling Results at Mutanga Project, Zambia

- Denison Mines Corp. Comments on Recent Market Activity

- Denison Mines Corp. Announces Approval of Midwest Joint Venture Environmental Assessment

- Denison Mines Corp. Announces Appointment of Steve Blower as Vice President, Exploration

- Denison Mines Corp. Reports Second Quarter 2012 Results

- Denison Mines Corp. Provides Date for Second Quarter 2012 Results and Conference Call

- Denison Mines Announces Closing of Transaction

- Energy Fuels Inc. and Denison Mines Corp. Announce Receipt of Final Order

- Denison Mines Corp. Announces Shareholder Approval of Arrangement

- Energy Fuels Inc. and Denison Mines Corp. Execute Definitive Arrangement Agreement

- Denison Mines Corp. Reports First Quarter 2012 Results

- Denison Mines Corp. Provides Date for First Quarter 2012 Results and Conference Call

- Energy Fuels Inc. and Denison Mines Corp. Announce Transaction to Create Leading U.S. Uranium Company

- Denison Files Annual Report on Form 40-F

- Denison Mines Corp. Reports 2011 Results

- Denison Mines Corp. Provides Date for 2011 Results and Conference Call

- Drilling at Wheeler River Intersects 25.8% eU3O8 Over 4.9 Metres and Expands Phoenix Zone A Deposit

- Denison Announces 28.2 Million lb. Increase in Inferred Resources on Mutanga Project, Zambia

- Denison Announces Start of 2012 Drilling Program at Wheeler River

- Denison Outlines 2012 Operating Plans and Releases Final 2011 Production and Sales Volumes